Description

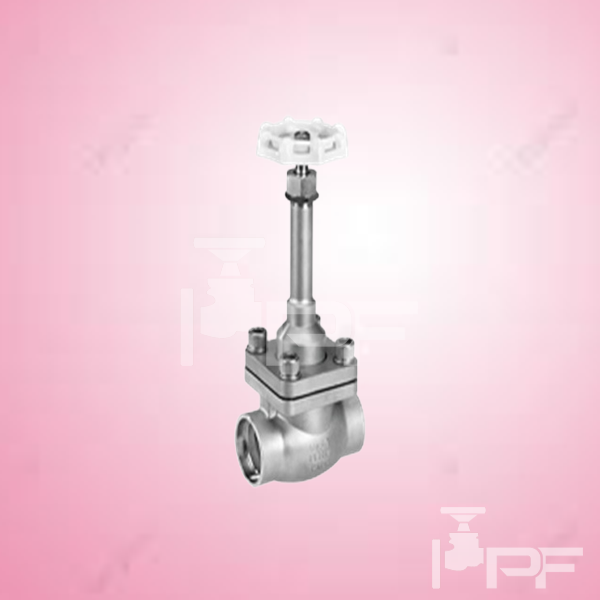

Description – Cryogenic Butt Weld End Globe Valve

Material – Stainless Steel, Carbon Steel, Hastelloy

Gasket – PTFE, EPDM, Viton

Size Range – 1/2″, 1″, 1 1/2″, 2″, 2 1/2″, 3″, 4″,6″, 8″

Application – Chemical Manufacturing, Food Equipment, Pharmaceutical, Petrochemical, Steel Manufacturing, Distilling, Food and Beverage, Pulp and Paper Processing, Power Generation, Marine, etc.

Operating Type – Manual On/Off Valve with Handwheel

Interior Smoothness – 20Ra to 32ra

Max. Pressure – 150PSI to 5000PSI

NOTE : User to verify the compatibility

The Extended stems enables the valve function with insulation around the process pipe and valve to effectively minimize heat transfer and ensuring the transfer media remain at their required cryogenic state.

Cryogenic Valves designed for ultra-low temperature applications, providing highly reliable sealing performance. They are typically used by users handling liquefied or compressed natural gas (LNG or CNG), which is stored in cryogenic environments. The materials and construction of cryogenic valves must meet the highest quality and safety requirements to ensure that they can safely hold cryogenic media, such as liquefied natural gas.

Our cryogenic valves pass the BS 6364: 1984 cryogenic test and can be used in temperatures as low as 384°F/-196°C. Mize offers the PN50 cryogenic globe valve with two welding designs: Socket Weld and Butt Weld. Both are made using the highest quality ingredients. This material conforms to ASTM A351-CF8M.